Writing / Irene Vega

Clean hydrogen, also called green hydrogen, can play a key role in the decarbonisation of various sectors, as intended by the European Commission and the 2030 Agenda for Sustainable Development. This type of hydrogen can be obtained through various processes, such as electrolysis driven by photovoltaic energy, biomass gasification, artificial photosynthesis or through thermochemical cycles driven by solar thermal energy. In this last alternative, a solid material is capable of being reduced at high temperature -releasing oxygen- and reoxidized when it comes into contact with water vapour, recovering its initial structure and producing hydrogen. This process has the great advantage of obtaining hydrogen and oxygen separately, using only water as a sustainable raw material. However, its main problem is that it requires very demanding operating conditions in terms of temperature (usually above 1000-1200 ◦C).

Currently, new materials capable of being reduced in the first stage of the process at temperatures below 1000 ◦C are being explored and developed, maintaining a considerable production of hydrogen, in a stable and sustained manner during a large number of consecutive thermochemical cycles of reduction and reduction. oxidation. In this line, the Chemical and Environmental Engineering Group (GIQA) of the URJC has managed to prepare active materials for the production of green hydrogen by means of thermochemical cycles at a temperature notably lower than that usually used, lowering the thermal requirements of the process to 800 ◦C. This supposes not only an increase in the efficiency of the process, but also enormous advantages when it comes to considering the implementation of these processes on an industrial scale, given that these operating temperatures are compatible with those that can be reached in currently operating solar energy installations. thermal concentration, such as solar tower plants or parabolic dish plants.

As the researchers explain, this system implies "lower radiation losses and better absorption of solar radiation." In addition to that "the technical requirements of the construction materials of the reactor are reduced", which translates into a reduction in costs. This resultsrecently published in the scientific journal CatalysisToday, have been obtained from the preparation of perovskite-type materials, which are characterized by their good ease of being reduced and oxidized (redox properties), managing to significantly reduce the high operating temperatures in obtaining thermochemical green hydrogen. All this has been carried out thanks to funding from the European Union and the Community of Madrid within the framework of the Multiannual Agreement with the Rey Juan Carlos University in line of action 1, Program for "Encouragement of research by young doctors ” (ACES 2030 (S2018/EMT-4319) and M2174 SolToComb).

Perovskites, versatile materials for the exploration of new uses

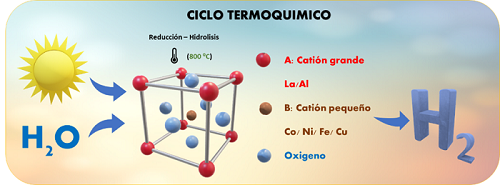

The materials studied are based on metal oxides with a perovskite structure type ABO3, (as shown in the image). On the initial formulation -with lanthanum (La) in position A and other metals such as cobalt (Co), nickel (Co), iron (Fe) or copper (Cu) in position B- aluminum (Al) has been introduced in the perovskite structure to modify its initial properties. Perovskites with high reduction and oxidation capacity at low temperature (from the point of view of concentrating solar energy) have been achieved, with stable hydrogen production and without apparent damage or loss of activity during consecutive cycles. "This confirms that perovskites are very interesting materials for the large-scale production of hydrogen from the dissociation of water through thermochemical cycles driven by solar energy at low temperatures," the researchers point out.

Image: Thermochemical cycle of hydrogen production using ABO3 perovskite-type materials.

This process opens up new possibilities for reducing carbon dioxide emissions, since thanks to the production and use of hydrogen as an energy vector for different applications, it would contribute to decarbonizing the economy and complying with the European Green Deal for climate neutrality by 2050. .