|

Responsible: Claudio J. Munez Address: c/ Tulipán s/n. Mostoles 28933 Department: Department of Chemical, Energy and Mechanical Technology Phone: 91 488 71 77 |

|

Essays/Services offered

The Mechanical Integrity Laboratory includes all the experimental techniques necessary for the correct development of the research work of the Group of Durability and Mechanical Integrity of Structural Materials of the Rey Juan Carlos University. It is a multidisciplinary group dedicated, mainly, to the study of new materials for structural application, as well as to the improvement of experimental techniques that allow characterizing their behavior under different stress conditions and/or aggressive environments. The LIM has modern and sophisticated equipment that allows mechanical and degradation tests to be carried out under very different conditions of temperature (-170 ºC – 1300 ºC), load (from mN to hundreds of kN), deformation speed (from 0.1 s- 1 up to 1000 s-1) and stress (traction, compression, bending, torsion, fracture mechanics and fatigue, wear, etc.). In addition to the testing techniques, the laboratory has been equipped with strain measurement techniques using video strain gauges using high and low acquisition speed cameras. This allows displacement and deformation fields to be measured "in situ" in all types of tests, including those carried out at a high rate of deformation (impact tests).

Likewise, the LIM has the necessary support equipment for the preparation of samples (precision cutters, fillers, etc.) that allow the adaptation of the samples to the test equipment, or the surface preparation for the observation of the materials. using the different microscopy techniques available in the laboratory

In short, the equipment included in the LIM allows a comprehensive characterization of all the relevant aspects of a material that define its possible use in structural applications.

It is also important to note that the Laboratory has an area for manufacturing coatings using thermal projection techniques that allow all types of materials (metallic, ceramic, etc.) to be deposited on a substrate in a controlled manner, since the projection equipment is handled in a controlled manner. robotic form.

From all of the above, the objectives of the laboratory are deduced:

- Support for research, as technological support for the research projects developed by the DIMME.

- Support for teaching, as an instrument for carrying out final undergraduate or postgraduate projects for students of the different degrees taught by the teaching staff linked to the DIMME.

- Provide service, as a testing laboratory, in aspects related to the mechanical characterization and structural integrity of components and materials, as well as provide advice on those aspects related to the manufacturing, processing and service behavior of materials and components.

The LIM has had various quality systems active. Since its creation and until 2012, it was accredited by ENAC under standard 17025, the scope of which included carrying out various mechanical tests. Subsequently, and until 2018, after extincting the previous system, it maintained a system based on ISO 9001 focused on the use and management of laboratory equipment. Currently, it maintains both extinct quality systems, but continues to carry out various tasks designed in them, such as, for example, periodic verifications and calibrations of experimental equipment and techniques.

The standard mechanical tests that the laboratory can carry out are:

|

METALLIC MATERIAL TESTS |

Standard or procedure |

|

room temperature tensile |

UNE-EN ISO 6892-1; ASTM E8 |

|

Tension and compression at different temperatures |

ASTM E21; ASTM E209 |

|

Vickers hardness |

UNE-EN ISO 6507-01; ASTM E92 |

|

microhardness |

ASTM E384 |

|

charpy impact |

ASTM E23 |

|

friction and wear |

ASTM G99 |

|

Fracture and fatigue at different temperatures |

ASTM E1820; ASTM E647; ASTM E466; ESIS protocols |

|

Hopkinson Bar Traction and Compression |

Own test method |

|

Removal of self-drilling and self-tapping screws on sheet steel |

Own test method PT-ME-04 |

|

POLYMERIC MATERIAL TESTS |

Standard or procedure |

|

Tension and compression at different temperatures |

ISO527; ASTM D638; ASTM D695 |

|

Fracture and fatigue at different temperatures |

ASTM D5045; ASTM D6068; ESIS protocols |

|

Impact |

ASTM D256; ASTM D6110 |

|

friction and wear |

ASTM G99 |

|

CERAMIC MATERIAL TESTS |

Standard or procedure |

|

Flexion, compression and diametral compression |

ASTM C1161; ASTM C1424; |

|

Fracture |

ASTM C1421 |

|

friction and wear |

ASTM G99 |

|

COMPOSITE MATERIAL TESTS |

Standard or procedure |

|

Traction |

ASTM D3039M |

|

interlaminar shear |

ASTM D2344M |

|

shear in plane |

ASTM D3518M |

|

Compression |

ASTM D3410M |

|

Traction-traction fatigue |

ASTM D 3479 |

|

Fracture and interlaminar fatigue |

ASTM D5528, ASTM D6115 |

|

New techniques |

Standard or procedure |

|

Erosion tests at room temperature with different angles of incidence Traction |

ASTM G76 |

|

Shear test in bimetallic joints (Triple Lug Shear) |

MIL-J-24445A |

Our Team

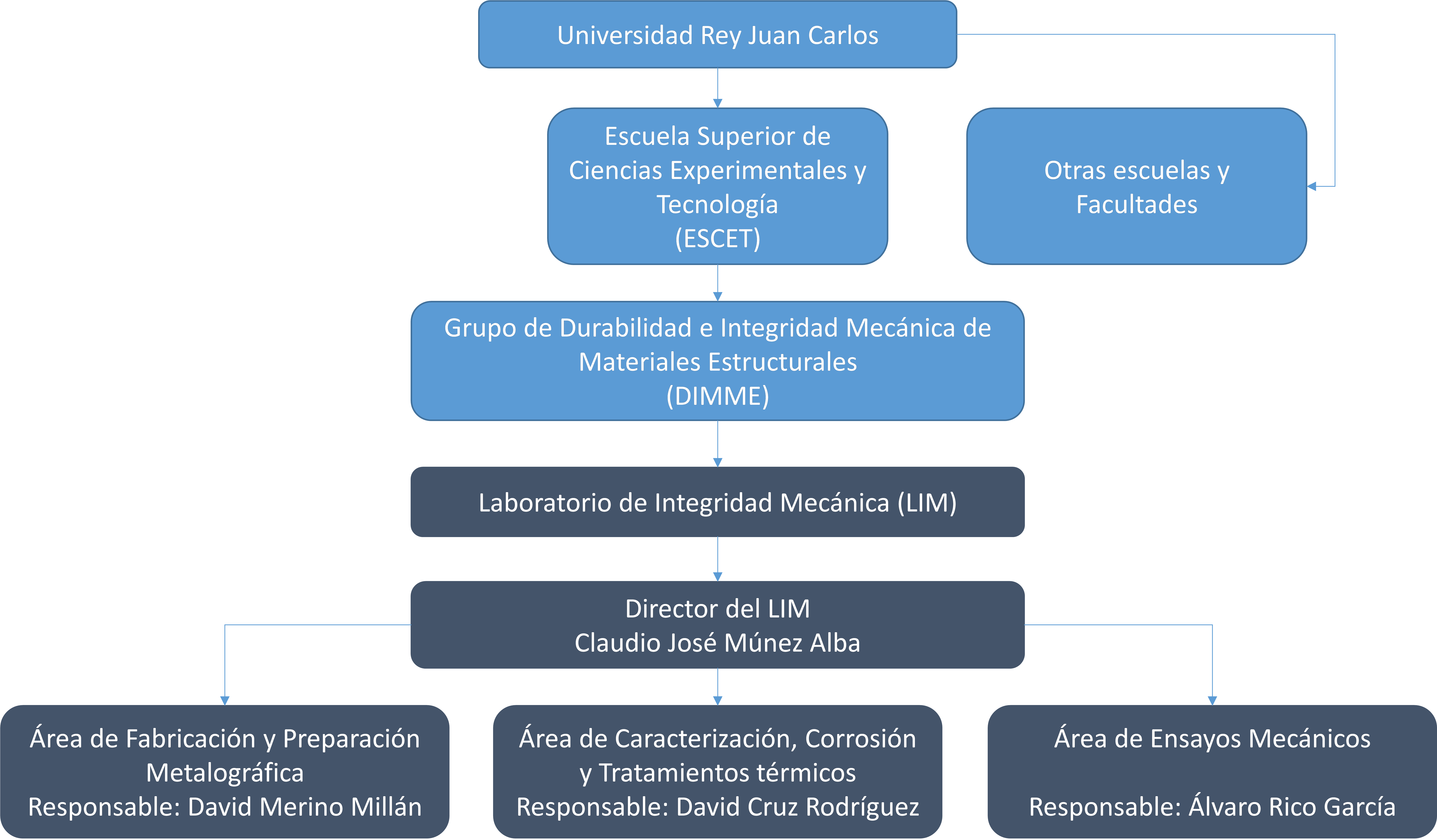

The Mechanical Integrity Laboratory depends organically on the Superior School of Experimental Sciences and Technology of the Rey Juan Carlos University. It has a qualified staff, with experience in the management of testing laboratories and, additionally, with experience in the development and support of research projects. Figure 1 shows the organizational chart of the laboratory in which its organizational dependency within the University is also made explicit.

Figure 1. Organization chart of the Mechanical Integrity Laboratory.

Available equipment

Mechanical testing area

- Hydraulic Testing Machine (MTS)

- Electromechanical testing machine (MTS and Galdavini)

- Hopkinson Traction Bar

- Compression Hopkinson Bar

- Durometer (Instron)S

- Microhardness tester (Buehler)

- Nanoindenter (Agilent)

- Tribometer (Wazau)

- erosion equipment

Manufacturing and metallographic preparation area

- Compact plasma projection equipment (Sulzer-Metco) placed on a 6-axis robot (Kuka) to generate metal coatings.

- HVLP gun to apply paints.

- Blast cabinet (Guyson)

- Planetary Ball Mill (Fritsch)

- disc cutter

- Disc Micro Cutter (Buehler)

- micro string trimmer

- Microtome

- Hot filler (Buehler)

- Automatic polisher (Buehler)

- printers 3D

Area of characterization, corrosion and thermal treatments

- Optical microscope and metallographic loupe (Motic)

- Image analysis (Motic and Nikon)

- Atomic force microscope (Park – XE100)

- Coating adhesion tester (Defelsko)

- Roughness meter (Mitutoyo)

- Potentiostat/galvanostat (Metrohm Autolab)

- Stove up to 250 ºC (Selecta)

- Oven up to 750 ºC (ThermoConcept)

- muffle

- High temperature furnace (Lenton)

- Thermal shock furnace (Lenton)